- Why the Led light you bought are easily broken ?

- Which parts are mostly easy broken for led light ?

- Why most suppliers can only offer you three years warrantee for the led light?

- Why led driver is so important for led light?

You will find the answer here!

- Most Led light include led lamp and led driver

- Led lamp Life time usually is 30000-50000hours. If use 30000hours one day 12hours use, can use 6years.

- Led driver of commercial lighting in the market usually offer 2-3years guarantee, So led driver life to decide the light life.

- Top Class driver can offer 6years guarantee . (Such as Meanwell street light Driver and so on, but the cost is 4-6 times than common driver).

- So good led driver can save energy and enlarge the lifetime for the whole light.

- But bad led driver will cut your light life, very easy to broken .

Then What is a good led driver ?

Here list for you to know the key point for the driver

- Driver PCB board Electrical Circuit design will affect led life time directly.

- Led driver included the digital driver and simulate driver.

- Digital Driver combine digital dimming control, RGB full color control.

- Simulate driver combine AC constant current driver and DC constant current driver.

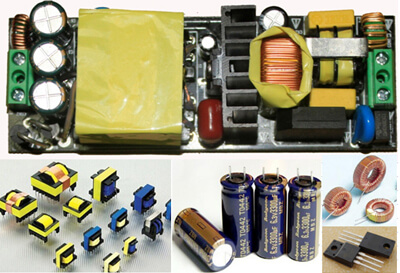

- The Driver was made by semiconductor component, resistance, electric capacity, inductance and so on.

- Any component broken, all the driver function or some function will didn’t work.

- The Led Driver Hot Dispel Problem

- Led is cold lighting source. The work temperature can’t over a level.

- Some Led light suppliers do not professional, do not know how to design the led light and driver. so they just buy spare parts from others, no detailed design will make the hot dispel problems easy happen, and the light will be easy broken.

- Other lighting factory can make driver by themselves. So they consider the driver at the beginning of design. In the design, must consider Led hot dispel and also Driver Hot Dispel, then can design the good driver.

- The Led Driver Power factor Design

- Although led light efficiency is higher, still have 80-85% heat energy consume,

- Make inner lighting temperature increase 20-30℃. If the room temperature is 25℃, inner of lighting will be 45-55℃,

- Led driver work under the high temperature for a long time, if want to keep the life time, just need to enlarge the power spare. Usually is 1.5-2 times spare.

- Electrical component choose

- If the inner temperature is 45-55℃, and the driver inner will still have 20℃ increase. So the component area temperature will reach 65-75℃.

- Some component parameter will change under high temperature, some life time will be short.

- Choose the electrical component must can work under high temperature with a long time.

- Here please take more care for electric capacity and cable.

- Electric Current Need Consider

- Led Driver to Led lighting the main parameter is a constant current.

- The current decide Led brightness.

- So for one batch driver, the current deviation need keep in ±5%.

- Then can keep all lighting brightness same.

- PCB board Design

- Led lighting leave the space for a driver is very small (only extend driver except).

- So when design the driver, Safe spacing must be considered.

- Input and output separate driver need load 1500-2000VAC test, 3mm distance is necessary on PCB board .

- If the driver shell is metal, the whole PCB board must consider

- The high voltage parts has enough safe space to the shell. If no space, must use insulate glue or add insulate paper.

- All the hot components must arrange average on the PCB board. Electric capacity need to leave far from the hot components.

- Transformer

- From theory, the transformer is more bigger for same power is more better.

- Of course, the cooper cable must be pure. And also the wrap cable is good.

- Electric Capacity

- Rubycon capacity from Japan this is the best choic But cost is higher, and easy to buy the fake one.

- Beryl brand for the most supplier is a competitive choice.

- Inductance: Good inductance the cooper cable wrap very compressed and average.

- Mosfet Tube must take care of the hot dispel for high power.

- Good driver supplier will use the aluminum panel to make hot dispel.

- Certificate

- For LED Driver CE,SAA and UL is the popular certificate use for Driver now.